| MATERIALS

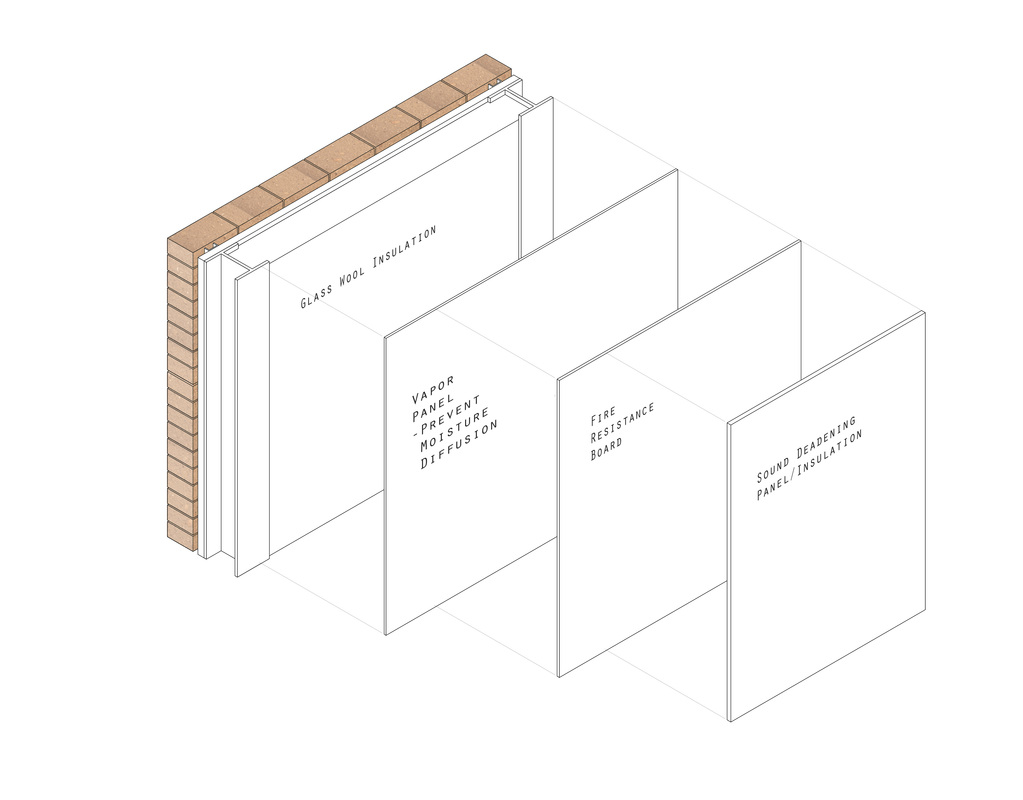

The image, presented far right, is that of a material breakdown, presenting the different surfaces that compose the entire external wall, from the inner leaf.

The first layer that attaches itself to the steel columns of the Pavilions overall structure, is that of a 'vapour' Panel that is explained in more detail below as a product. The reasons for such a material to be included within | the pavilions composition, is to stop moisture fro diffusing through the external leaf, affecting the materials, temperature and general atmosphere of the interior space.

The following layer, of which attaches to the vapour board behind it, also can attach to the steel frame and is the 'Fire Resistance Board' - again explained in more detail below. This is to withstand fire for a specified amount of time, found with the product research below. | | The Sound Deadening or Insulation Board has been explored and researched within previous posts ('Sound Control Walls') - See for Reference. | | | | KNAUF VAPOUR PANEL

As introduced above, the first layer that I have applied to the inner leaf of the envelope, is that of a moisture resistance or 'vapour check' board. A traditional plasterboard element, is layered with a 'metalled' "Polyester Aluminium Foil", that is laminated onto the back of the original product.

The introduction of such a material, allows for a significantly limiting, or reduction, in the volume of moisture that can

| diffuse through the layer and begin to affect and damage the accompanying materials and surfaces of the external envelope, as well as other interior fabrics or materials. In having no distinct graphic identity, seen within the diagram above, as well as the image provided (left), I have presented this product as a vertical plane, similarly to the others of the walls composition, although the dimensions have been kept strictly accurate to the specifications outlined upon the provided website. | | | This 'Aluminium Foil' can be seen even clearer within the image provided on the right, of the actual product that is said to also counteract as a a Fire Resistance Strategy also, although I feel it important to not reply upon one material for both equally as important | functions. The following is to assess the costs of this product implemented within the pavilions design, to achieve a greater understanding of the technical and financial requirements of a development of this scale and type. | POTENTIAL COSTING

The website provides prices for specific dimensions of this product, the one being represented within the axonometric graphic above, being of 15mm x 1200mm x 2400mm.

The Price of this panel size is - £12.19 (External Wall is Approx. 13x2.1)

13m ÷ 2.4m = 7 (6.19) Bottom Row of Panels

7 x 2 =14 Both Rows of Panels

Require approximately 14 panels at £12.19 each = £170.66

Total Cost of One External Wall = £170.66 for 14 Knauf Vapour Panels.

| The figure provided (£170.66) is to be added to the JCW Silent Board prices that can be seen within the 'Sound Reduction Walls' Post. The total of that product came to £1,430, to insulate the same external wall using approximately the same dimensions and figures in which to calculate the cost of the inner leaf, the most important aspect of this project in terms of quality of atmosphere created. | | FIRE RESISTANCE BOARD

A sheet material such as a Fire Resistance Board, as well as the Vapour Check seen above, is part of contemporary building rules and regulations, as to withstand fire damage for a period of time before allowing it to begin to damage any integral structural elements of a building.

The product that I have researched as for a suitable fire resistant board, is that of | Promat SUPALUX, seen within the image presented, right. Unlike other products that I had explored, the 'SUPALUX' is applicable to both internal partitions, as well as the buildings external envelope, allowing it to be relevant in all spaces of the pavilions technical design.

As well as providing up to 240 minutes worth of fire resistance (in the event of), the Promat product also boasts a vast | | | | The following, is a presentation of the estimate costs involved with the implementation of Promat SUPALUX Fire Resistance Boards within the external wall of the Pavilion.

Boards of 2500mm x 1200mm x 12mm - Sold in sets of 5 at £116.45

13,000 (Wall Length) ÷ 2500 = 5.2 (One Row)

5.2 x 2 = 10.4 Boards for external wall interior

10.4 x £116.45 = £1211.08 (£1211.00)

Total Cost of One External Wall (Interior) Fire Resistance Panels

£1211.00 | | array of specialities within terms of insulation, protections and resistance, most interestingly I found, in having a notable, high impact resistance, in being such a strong material.

Used within construction for approximately thirty years, the Promat SUPALUX is a tried, tested and renowned product that I feel suitable enough to

| retain the atmosphere and environments within the pavilions proposal and design.

With an ease in assembly, both technically and manually in how the boards are attached both by workers and onto the structure, is efficiently ergonomic, leading an exploration into the price of such a valuable product. | |

|

RSS Feed

RSS Feed