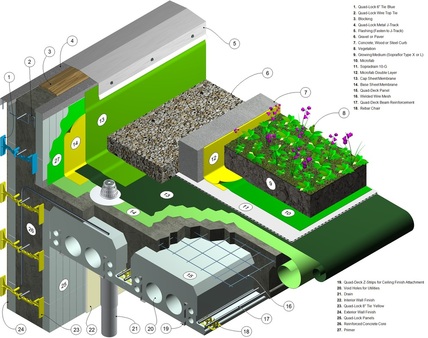

| All the information regarding Green Roof requirements is sourced from the following website, http://www.greenroofguide.co.uk/design/, although it has an entire focus upon Green Roofing and not the garden roof that I am beginning to tectonically plan and design within the following posts. However, as Green Roofs must accommodate the weight of the vegetation, soil and perhaps in some cases, the live loads of human maintenance, I felt that this was still relevant and an informative representation of Green Roofing requirements and considerations. | The space above my kitchen, and seen within my final design panels (IDS Design Panels tab) has been developed throughout the project as a Green Roof space, or more specifically a Roof Garden, that due to its purpose of being an outdoor environment, was ideal to provide more facilities and activities within my final Pavilion Design without eating into the maximum heated floor space restriction. The two images to the left, one of which being of one of the several roofs of the 'Rockefeller Center' New York City, provides a clear basic understanding of the visual impact and atmosphere, that I want to create within my Roof Garden space - although this will be in an opening and not entirely wrapped by the context of a city. However, due to my use of Rammed Earth, and it being unsuitable structurally to support such a load alone, I will be exploring the connection between a roof and external wall to grasp an understanding of how I can design around this issue, as well as with the use of a steel skeletal framework. This would allow me to then begin to sketch and organise the section of my external wall, to be uploaded at a later date. |

| The image to the right, presents a typical tectonic structure that sufficiently sustains a green/garden roof space. Although in terms of materiality (particularly in the use of reinforced concrete for the external wall itself) is is slightly different, this provides the most accurate basis upon which I can draft my own external wall section, roof connection included. The most interesting aspect that I found within the following image, is that of the roofing structure below, consisting of a largely concrete entity, entitled 'Quad Deck Panel'. |

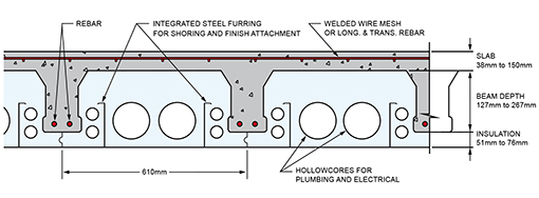

| The information below, on the 'Quad-Deck' panel, is derived from the following website - http://charconcs.com/roofing-solutions/quad-deck-roofing. Although it is a product and therefore is biased towards its characteristics as a constructional material, the reduction in the use of concrete, I feel, sits comfortably within the almost environmentally conscious design that had been integrated within my Pavilion. | QUAD-DECK PANEL Produced with 40% less concrete that typical reinforced concrete platforms and blocks suited to the supporting of decked roofing, the 'Quad-Deck' panel is a lighter, more efficient and innovative alternative to reinforced concrete. The image to the left, presents an illustrated and annotated section presenting the features seen above, within the green roof graphic. |

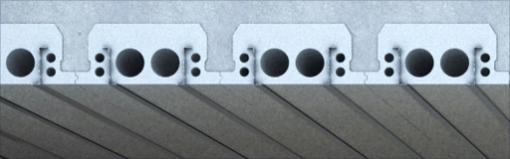

| Made of Expanded Polystyrene, each individual panel is attributed with two steel beams, sunken within them as to reinforce the concrete, garden and live loads that it will eventually have to sustain and support. These beams can be seen within both of the images, above and left, as S sections, sitting either side of the hollowcores that penetrate the entire length of the panel (seen and explained within the annotation above). The inclusion of hollowcores, allowing for services (such as 'electrical' and 'plumbing' - see annotation) presents it as an entirely functional and almost competitive alternative to 100% reinforced concrete suspended panels that are commonly used. The Quad-Deck product, as explained throughout their website, is also, due to its design, an easily assembled component in terms of the duration of time on site. This also has financial repercussions in that less time on site is equal to less man hours and therefore, lesser labour costs, as a result of the 40% less concrete used than that in 100% pre-cast concrete slab roofing. However, depending of the climate and environment of the build, the setting of the concrete and the structure as a whole to allow it to become able to sustain such loads, is around 3-7 days. The 'T' beam concrete sections, completed with reinforcement bars seen within both the above and top right image, are the resulting 60% concrete that remains, significantly reduced to the EPS blocks. These concrete 'T' beams, create a sheer plane in which provides a suitably supported surface for a Green or Garden Roof. Above, is an image of the EPS block work, being prepared for the addition of 'Rebars' and then the T slabs of concrete. | The image below, presents a more realistic render of how the steel sits within the EPS (Expanded Polystyrene It is this element that creates its almost reinforced concrete like strength. Below, is a concrete roofing project produced by the same company, (Charconcs) although employing a slightly different method entitled 'Quad-Lock', suitable pitched roofing although retaining almost identical materials, perhaps showing the versatility within the product as a whole. http://www.quadlock.info/photos/albums/Quad-Deck/misc/Deck_Roof_Poor.jpg As well as providing sufficient load supporting, reasonable spanning distances (of up to 9.5m) and reducing its 'Floor Mass Dead Load' by up to 50% - a drastically important figure when considering the steel framework that my design consists of, this 'Quad-Deck product also acts as a sufficient thermal and acoustic insulator. In having such low U-Values (of a scale from 0.35-0.17) and providing the required thermal capacity of such a structure, the acoustic insulator feeds well into the atmospheric qualities that the kitchen and dining space below is proposed to possess. |

RSS Feed

RSS Feed